June 25, 2024

Parts shortages and Supply Chains

There are growing fears that supply chains are being disrupted enough to affect production again. Companies are complaining that they cannot get parts and other inputs on time.

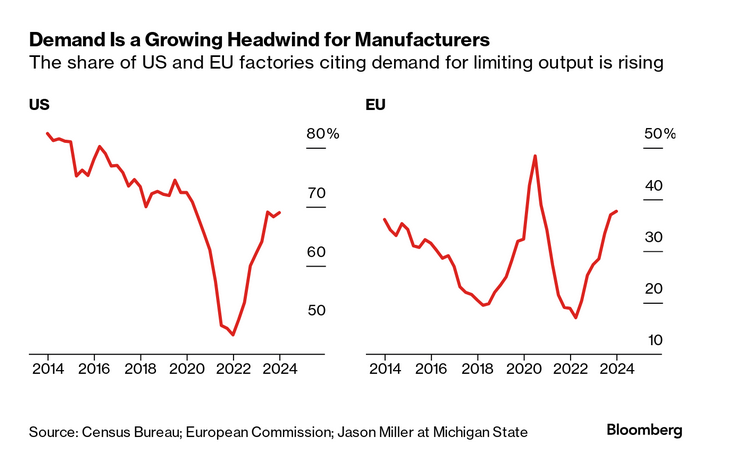

Demand for inputs by producers has not been stable in the USA and the EU for a long while, but recent fluctuations in reliability of supply chains have meant that shippers are having difficulty allocating capacity correctly.

The "higher for longer" mantra at central bank interest rates have driven the economies of the world into recession in their misguided attempt to deal with inflation through economic suppression. Manufacturing surveys released earlier this month show decline in demand for inputs almost across the board, but at the same time these producers are reporting it is harder to find suppliers when they do need those inputs.

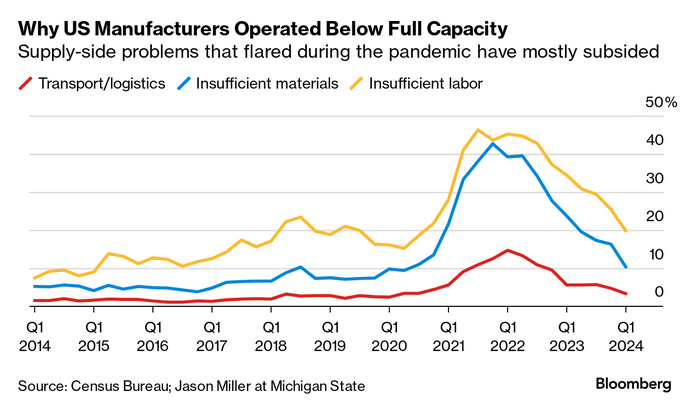

For mainstream economists that blamed the supply crunch for inflation, those have declined almost back to pre-pandemic levels, which should indicate that their contribution to inflation is declining. However, the declining strain on supply chains is due to slowdown in production, not eased shipping.

Some economists in the shipping sector are predicting that it takes about 6-9 months for prices from increased shipping costs to reach consumers (because of the systemic-level impact on planned inputs).

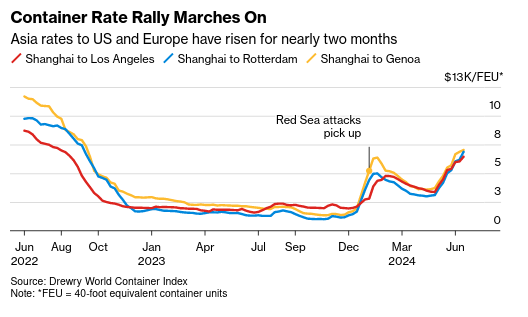

However, spot rates on shipping containers are the highest they have been since the major supply crunch in 2020. Part of the reason for this is that shipping companies and container companies are in contract negotiations. The other reason is that while demand is soft, the affect of war and climate is increasing risk of supply chain instability.

Such instability of routes means earlier ordering and more storage, which means increased costs.

Airlines are still struggling with this concept as they continue to try to find savings for inputs through fraudulent means instead of shoring-up production closer to their assembly.

The manufacturer warned late on Monday that it’s experiencing a shortage on engines, aerostructures and cabin interiors, which in turn is sabotaging the company’s delivery plans.

Faury said that cabin parts, for example, are in short supply because airlines are refurbishing older planes, meaning shipments to Airbus are constrained. Many airlines have complained that aircraft deliveries are delayed, forcing them to fly older kit for longer. (BN)

New shipping fleets are being launched next year, but the increased capacity on the seas does nothing if your boats cannot move.

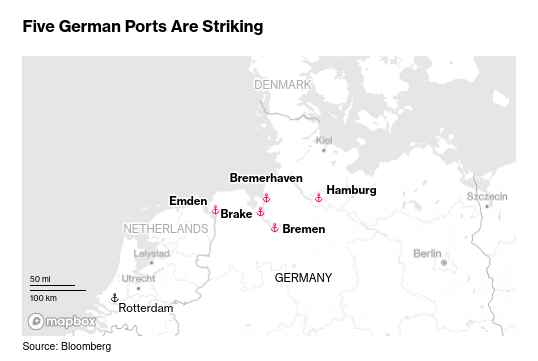

Speaking of freight not being able to move, Verdi German workers are striking five major ports in the north of their country for over a week. The impact is being felt at the cost of $6B worth of trade being disrupted.

But, any strike action pales in comparison to the impact of Red Sea disruption as the impacts on strikes are dealt with at the end of dispute and the fact that they are known quantities when it comes to timing and effect. The Red Sea issues caused by the war in Gaza and the Houthi rebel attacks are of an unknown length of time or effect, impossible to plan for, and not easily resolved.

Data released earlier this week for May shows that revenues of the Suez Canal dropped by 64.3%

The issue for supply chains right now is they are not resilient and we are doing little to make them more resilient.

For example, digital traders are increasing their use of sophisticated data tools to speculate on spot prices for shipping containers. This creates market mechanisms for allocation of shipping, but in the end just undermines the investment in resilience across the system. These kinds of speculative markets make it seem like there is a sophisticated use of slack in the system, but that just means the entire system is more susceptible to localized disruption because there is never any slack to absorb those disruptions.

All this is to say that we have a problem in our supply chains created by shifts in trade routes because of geopolitics, war, re-introduced tariffs, the end of the "just in time" experiment, lack of interest by companies to plan for disruptions, and a climate change-related crisis. Add to this that there has been significant reorganization of the supply chain systems already because of the pandemic and we have all the ingredients for reliving a full blown supply chain crisis.

There is a pause on this crisis appearing right now because the economy is struggling. But, the only way that we can make use of this pause and fix things is through investment in resilience and recognizing the negatives of neoliberal trade programs.

Unfortunately, instead of making those investments, shipping companies are attempting to point fingers at workers and demanding the end to labour rights and increasing the use of unsafe conditions such as using longer trains or attempting to replace inspection with AI/automation.

The only way that things are going to get better is if we have governments that start to use their regulatory and investment capacity to build the supply chains and infrastructure we need.

Marine Road Rail

Marine Road Rail