January 31, 2024

St. Lawrence Seaway 2023 Season

- 2023 was the longest season in history.

- Montreal Locks closed on January 5.

- Welland closed January 7.

- 38M tonnes of cargo moved through the Seaway in 2023

- 3.4% increase over 2022.

- Great Lakes and St. Lawrence Seaway support 246,000 jobs & US$36 billion in economic development activities across North America.

2023 Results Highlights

- Grain: Despite challenges posed by climate change, producers successfully mitigated global issues, resulting in an overall increase of nearly 5% compared to 2022 figures, reaching 10.4 million tonnes. Notably, Canadian grain experienced a significant year-over- year growth of more than 11%.

- Dry Bulk: Agricultural and construction supply chain materials, including potash, gypsum, cement and stone, exceeded 12 million tonnes, representing 5% growth compared to 2022.

- Liquid bulk: 3.6 million tonnes of liquid bulk transited the Seaway in 2023, representing a 3.4% increase from the previous year. Petroleum products were the primary contributors with 2.6 million tonnes, followed by liquid chemicals, which increased 11%.

- Cargo fluidity: The Seaway system’s efficiency contributed to economic development on both sides of the border, with fewer transits in ballast and an additional 1.2 million tonnes of cargo.

Shipping established new normal of "around Africa" route

- Red Sea avoidance means an added two weeks of travel.

- Shipping rates have stabilized for now.

- Excess capacity is absorbing the difficult conditions.

However, if the Red Sea disruption continues throughout 2024, shippers predict difficult times for "holiday" season purchasing. Many new ships are coming online in 2024-2025 and old ones retired. This may cause a disruption in the supply and utilization of shipping fleets.

Chinese New Year is early February and will reduce demand during that week and the period after.

Longer routes take-up more capacity.

BYD has started procuring car shipping fleet

The Chinese electric car manufacturer BYD has moved to procure a growing fleet of car shipping boats.

Similar to those used at the CN autoports, BYD is using these boats to deliver cars to different markets around the world.

The owning of their own ships allows BYD to control delivery rates and destinations more quickly than other car companies who rely on contracted parties. There is currently a shortage of auto carrier boats.

In 2023, BYD exported over 240,000 vehicles, up from 55,000 in 2022.

East Palestine Report

New report from US DOT:

- High-Hazard Flammable Train Route Assessment and Legacy Tank Car Focused Inspection Program

- The program is about replacing DOT-111 with DO

The report highlights that the companies are on track for replacing the older tank car fleet by 2029.

There are economic (and some practical) challenges that block the full replacement of this fleet immediately. Mostly, it is just very expensive to retire these cars before their stamped end of life.

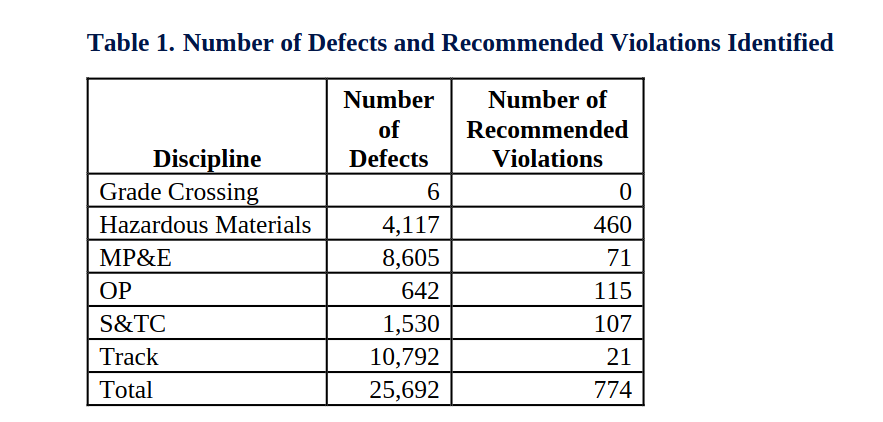

That does not stop violations racking-up along these routes:

This list does not include wayside detectors because the:

FRA regulations do not require the use of wayside detector technology.

Class I freight railroads and Amtrak have installed almost 16,000 wayside detectors (the bulk of which are hot bearing detectors (HBDs) and dragging equipment detectors (DEDs)).

- 6,400 Dragging Equipment Detectors (DEDs)

- 5,500 HBDs

- 1,600 Hot Wheel Detectors (HWDs)

Inspectors found 120 out of 2600 inspected defective (~5%), many for three months or more. FRA also found a complete lack of standardization of installation and maintenance of these detectors even within a company. And, few resources applied to managing data or the detector system. All told, the functioning of the detector system even of functional detectors is non-standard and inadequate. There is also limited (zero?) sharing of wayside detector information.

Inspection workers interviewed showed familiarity with importance of the information from wayside detectors and interest in using the information effectively.

FRA and PHMSA are seeking to establish regulations for wayside detectors.

The two most frequent defects inspectors identified were train consist inaccuracy, followed by not meeting safety and security inspection requirements at the time of a shipment’s pick-up or interchange, both of which are responsibilities of the railroad.

| Wayside Detector | Functionality |

|---|---|

| Acoustic Bearing Detector (ABD) | Detecting the internal defects of wheel bearings long before they fail, using acoustic technology |

| Automatic Cracked Wheel Detector (ACWD) | Identifying wheel flange cracks and internal defects by submerging the wheel tread through water |

| Dragging Equipment Detector (DED) | Detecting the components of rolling stock that are loose under moving trains |

| Hot Bearing Detector (HBD) | Detecting the wheel bearings defects, using an infrared thermal detection system |

| Hot Wheel Detector (HWD) | Detecting hot wheels due to locked or sticking brake shoes, using an infrared thermal detection system |

| Truck Bogie Optical Geometry Inspection (TBOGI) | Measuring the performance of car axles and wheel suspension using a laser-based technology combined with a high-speed camera along a tangent section of track |

| Truck Hunting Detector (THD) | Evaluating truck hunting behavior (measuring hunting index) using strain-gages or laser-based technologies |

| Truck Performance Detectors (TPD) | Evaluating the suspension performance of trucks along a S curve section of track (strain-gages or laser-based) |

| Weigh-in-Motion Detector (WIM) | Measuring the overload, side-to-side imbalance, or end-to-end imbalance condition of the cars |

| Wheel Impact Load Detectors (WILD) | Detecting the wheel defects (e.g., flat, shell, thermal cracks) by analyzing the wheel impact loads |

| Wheel Profile Measurement Systems (WPMS) | Measuring wheel profile defects (e.g., flange height and thickness, rim thickness), using laser and high-speed camera |

| Wheel Temperature Detector (WTD) | Detecting hot wheels (due to locked or sticking brake shoes) and cold wheels (inoperative brake system), using infrared scanning technology |

Marine Road Rail

Marine Road Rail