Safety technology in the rail industry? How, why, and for whose benefit?

Table of Contents

1. Current technology

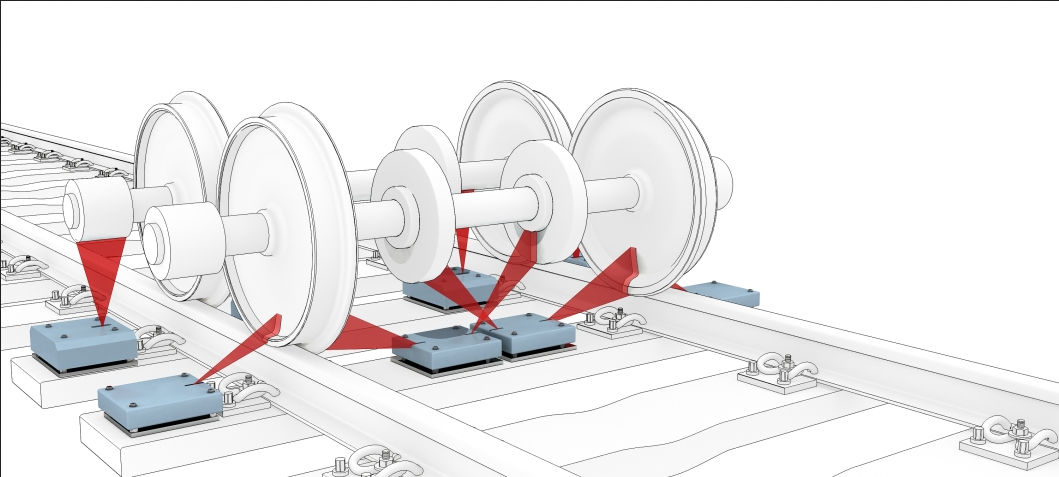

1.1. Wayside Detectors

1.2. Hotbox Detectors

- Alerts sent to crew.

1.3. Acoustic Bearing Detectors

1.4. Other

- Hot Wheel Detectors

- Dragging Equipment Detectors

- Wheel Profile Detectors

- Wheel Impact Load Detectors

- Proactive automated bearing algorithms

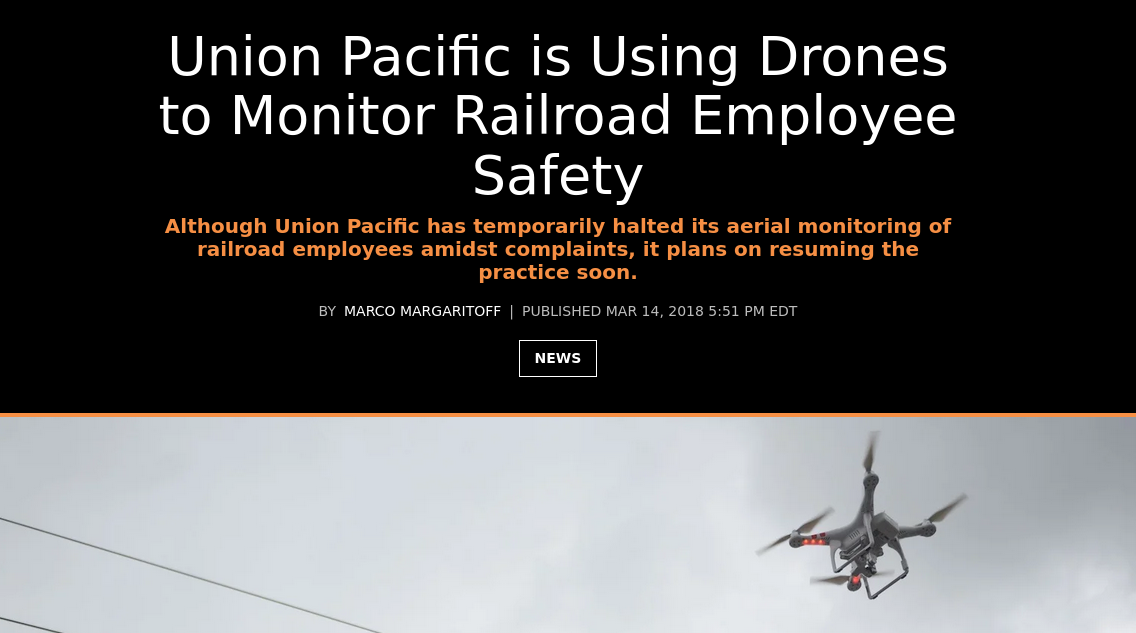

1.5. Drones

1.6. Automated train stopping technology

- Canadian Government 2022: starting to examine Enhanced Train Control Technology/Les technologies de commande des trains améliorée

- USA: Positive Train Control: fully implemented across the USA.

- Europe: European Train Control System: fully implemented.

- Wayside technology, track systems, signaling, and digital train monitoring feeds into this system.

2. Inspection Technology and Automation

2.1. Two futures are possible

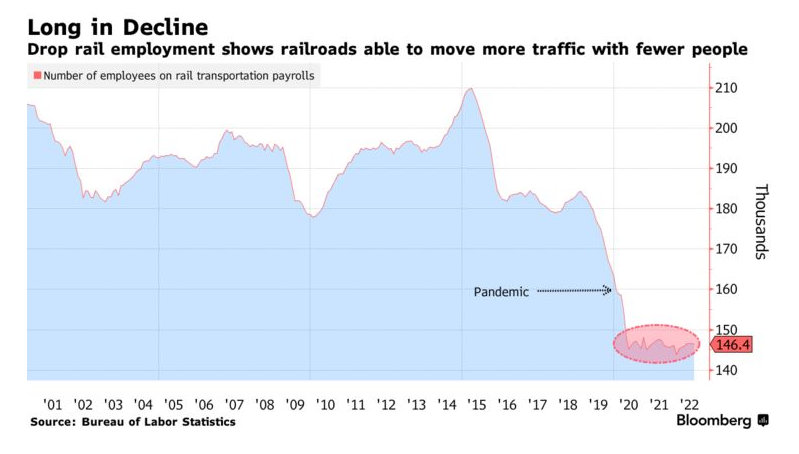

- Technology-focused where automation attempts to replace workers

- Safety-focused where technology augments and improves safety-focused performed by workers.

2.2. Rail Employers

Capital is firmly in the "technology should replace workers" camp:

2.3. Surveillance

- Safety being used as an excuse to monitor members on the job.

- Already abused for discipline.

2.4. Automation

- The promise of AI supported automation: fewer workers.

- Investment activity is in replacement, not augmentation or safety.

2.5. Reality

- Not possible to replace all workers with automation safely.

- Transport Canada's safety focus is reducing human mistakes (through culture)

- Companies' focus is reducing the number of people

- But, while all mistakes are human mistakes, humans also fix issues. You cannot take people out of the equation.

- The solution is usually more workers, redundancy, and technological supports, not the replacement of workers.

3. Rail Safety

3.1. Fatalities

- 3 workers killed on an average year in the industry in Canada.

- 8 workers are seriously injured on an average year in Canada.

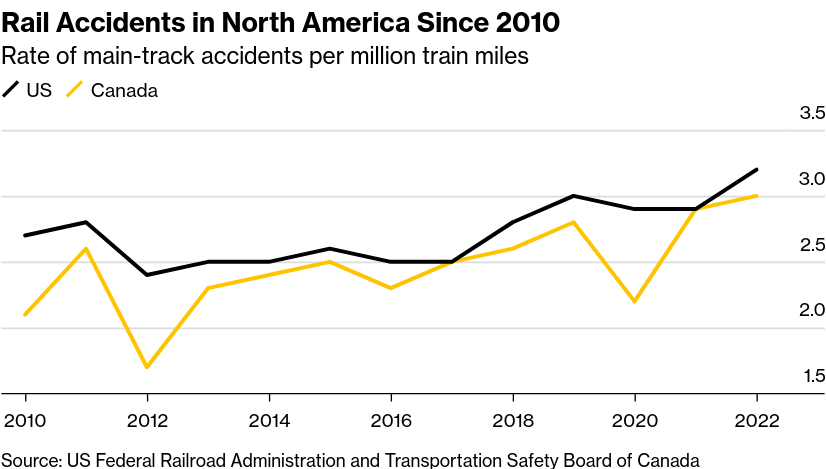

3.2. USA-Canada Accidents

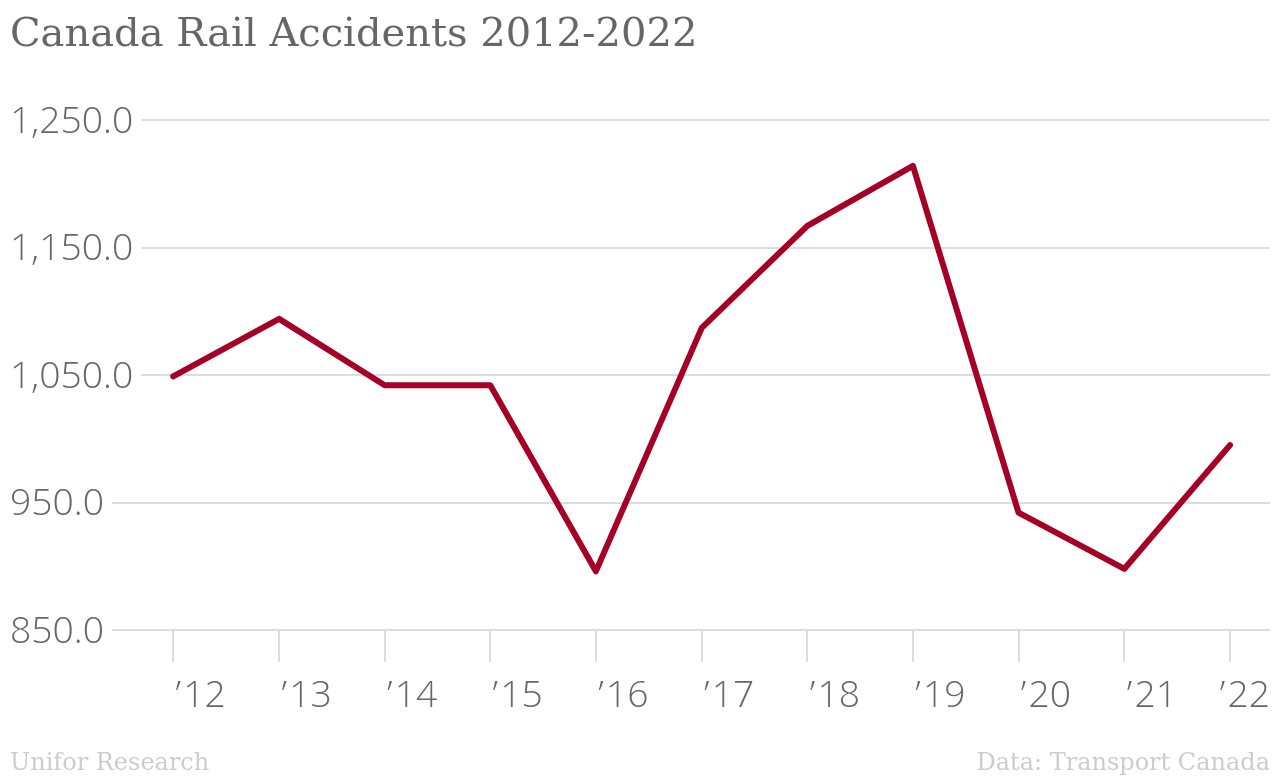

3.3. 2012-2022 Canada Accidents

3.4. Main Track Accidents per million track miles

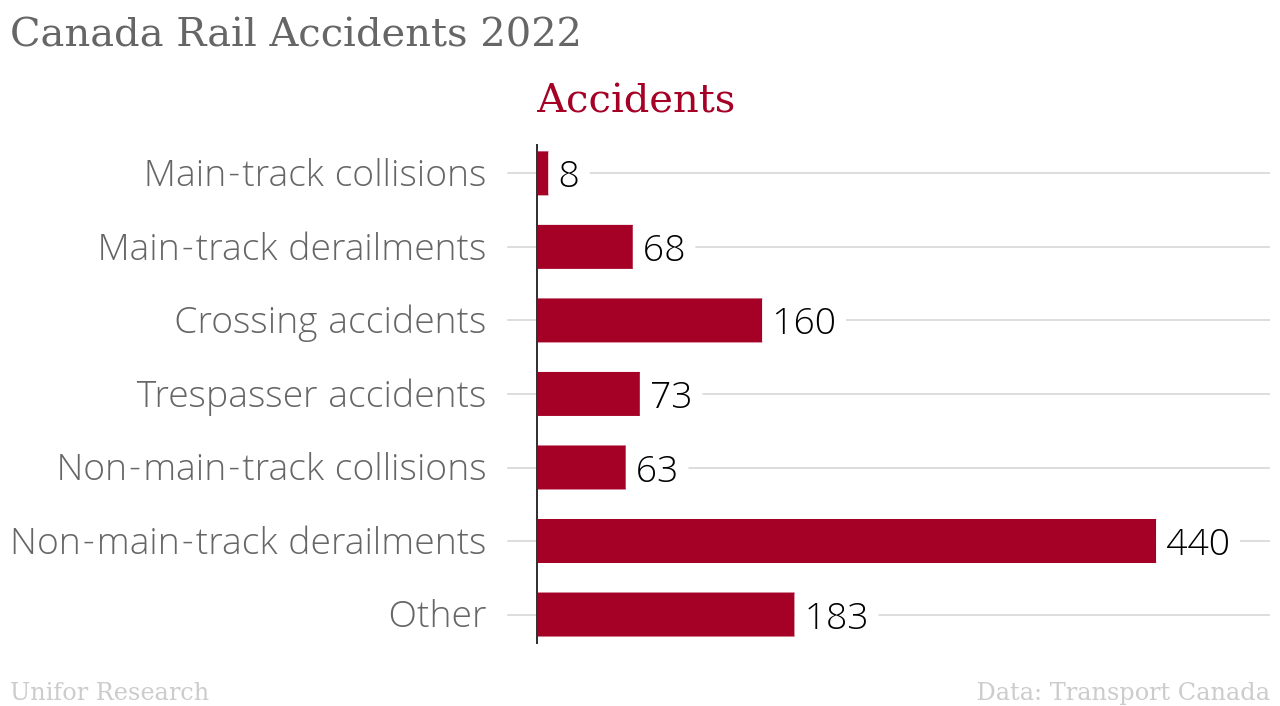

3.5. 2022 Accidents

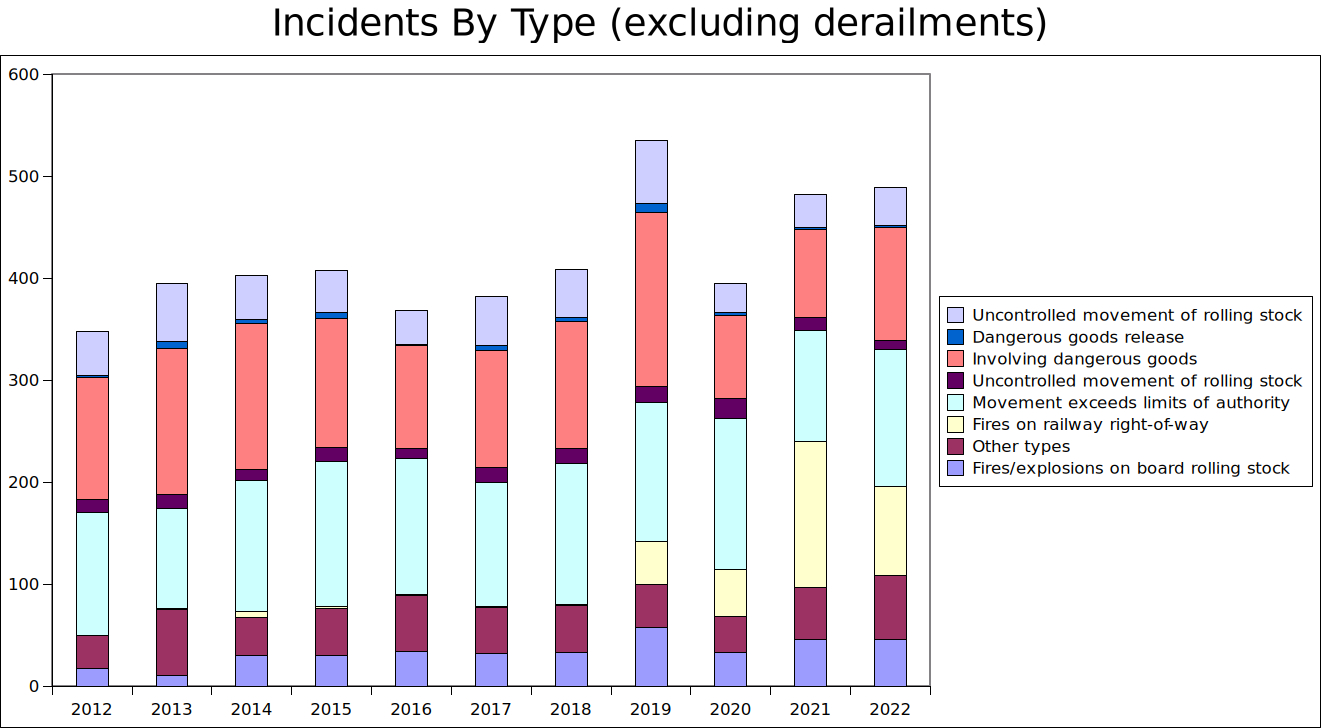

3.6. Accident by Type

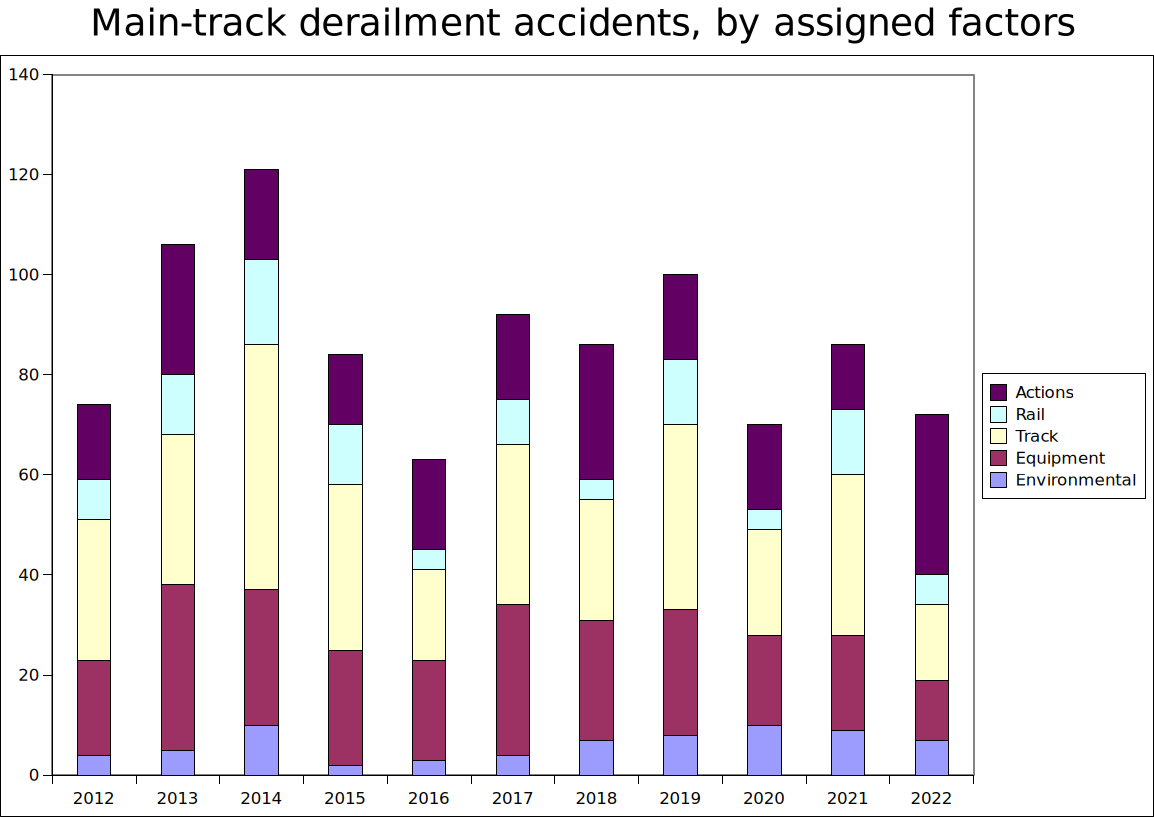

3.7. Derailments by Factor

3.8. Derailments and Technology

There were about 6,000 hot-box detectors placed along U.S. rail tracks as of 2015, according to a study by the Association of American Railroads (AAR).

The National Transportation Safety Board has pinpointed an overheated bearing as a critical contributor to last month’s accident. The train passed three hot-box detectors in the span of 30 miles before it derailed in East Palestine, according to the NTSB. Only one detector, right outside the Ohio village, recorded a “critical” high temperature. By the time the crew was alerted, it was too late to prevent an accident.

Their use contributed to a 59% decrease in train accidents caused by axle- and bearing-related factors since 1990.

4. Rail Inspection Automation

4.1. Automation and AI/Machine Learning Companies

- Duos Tech: duostechnologies.com

- Trimble: rail.trimble.com

- Brings together all current and new AI/Machine Vision inspection technology.

- In house developed (CPKC) inspection systems.

- Both are considered outsourced technology by companies, non-union.

4.2. CN

- Has 7 automated inspection portals (AIP)

- Produced by Duos Tech

4.3. CPKC

- Looking to replace Certified Car Inspectors with automation.

- Safety and Maintenance Inspections (S&M) exemption approved by Transport Canada for testing automation.

4.4. CPKC: Train Inspection Portal System (TIPS)

- Remote Safety Inspection

- Test focused on potash trains (602&603)

4.5. Remote Safety Inspection

- Information from the following is sent centrally via digital network:

- Cameras

- high-speed

- infra-red

- high definition

- Lasers

- Sounds

- Overloads metrics

- Dragging equipment detectors

- Brake tests

4.6. Four cameras

- Train view

- Truck view

- CSC (car structural components) view

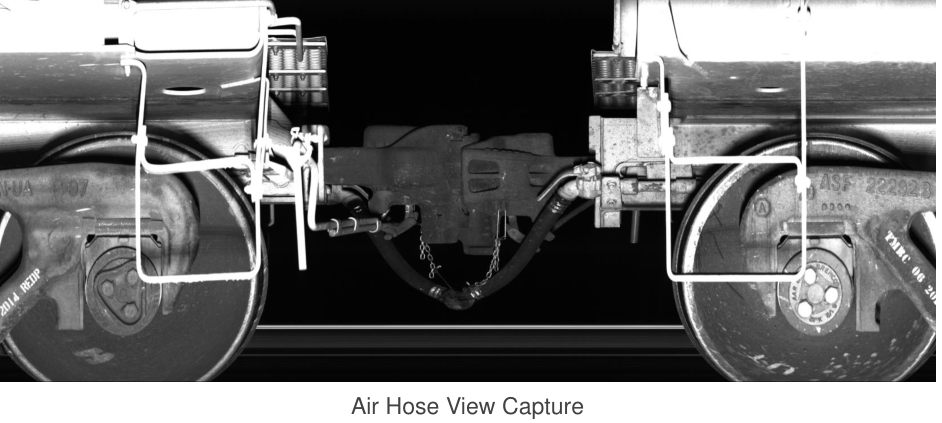

- AH (air hose) view

4.7. Images

4.8. AI/Machine Learning System

- Machine vision examines picture and compares it to databases of known defects.

- Automated flagging of problems.

- Signals sent to central office.

- Exception report sent to central monitoring office.

- Can have automated RSI Bad Order Car Repair report.

4.9. Replace workers?

- All four cameras need to be operating, or manual intervention required.

- All the following have to be working:

- Sensors

- Network connectivity

- Automated Wayside detector sites

- Still needs manual intervention if positive report filed.

4.10. Artificial Intelligence

- Just a computer program coded by people. Mostly untested.

- Sensitivity, precision, and accuracy can be tweaked to find more or fewer issues.

- Current system finds about the same number of issues as people: red flag.

- Self (un)regulated.

- All problems with AI apply to this technology in rail (hallucination).

- Still needs manual intervention, training, operation, maintenance.

5. Augmentation vs Replacement

5.1. USA Department of Transport

- Federal Rail Administration

- Volpe Center

- Teamwork is essential for safe operations across transport sectors.

- Human-Automation Teams (worker augmentation focused technology implementation) essential to train safety.

- Technology-focused implementation leads to negative unintended consequences.

- It is a policy choice to move to automation over safety and maintaining qualified workers.

6. Regulations

6.1. USA

- Fully regulated in the USA under the FRA Office of Research and Development and the Future Team.

- Best practices documents on implementation are provided by FRA.

- Testing and trialing technology alongside human inspectors is outlined.

- Specific demand that augmentation be the focus of technology implementation. Directive from the White House.

- Use of hot-box detectors not regulated and up to companies.

6.2. Canada

- Deregulation: seems to be purpose of Transport Canada and rail.

- Canada's Transport Canada has no equivalent office to the US DOT Volpe Centre.

- Transport Canada Innovation Centre is closest.

- Railway Ground Hazard Research Program: single focus research program on movement of hazardous materials via rail. Closed access academic research.

6.3. Railway Safety Bulletin

- 2019 was the latest Railway Safety Bulletin on Certified Car Inspectors:

Under subsection 18.2 of the Freight Car Rules, a railway company may use alternate methods or technology to perform all or part of a safety inspection provided the railway company engages in early consultation with Transport Canada to review the alternate methods proposed and file, at least 60 days prior to implementation, an alternative practice with the department. Such filing must demonstrate that the alternative method meets or exceeds the equivalent level of safety to the rule and must include a risk assessment as well as evidence of consultation with relevant associations or organizations.

6.4. 2018 Rail Safety Act Review: Main points

- Developing a better capacity in technology evaluation, data analytics (including predictive analytics), and human behaviour, to better understand the potential of new technologies to improve safety and facilitate their adoption in Canada;

- Transport Canada inspectors (Rail Safety Integrated Gateway, or RSIG).

- Latest focus is on people, not regulating safety infrastructure/equipment.

6.5. Canadian Regulatory Asks?

Safety review currently underway under Bill C-33.

An Act to amend the Customs Act, the Railway Safety Act, the Transportation of Dangerous Goods Act, 1992, the Marine Transportation Security Act, the Canada Transportation Act and the Canada Marine Act and to make a consequential amendment to another Act.

- The purpose of the act is to include digital and other "security" infrastructure under safety regulations. Making sure companies are putting digital security infrastructure to prevent/disclose hacking and the like—especially as they introduce more networked "safety" service.

However, the legislation could be amended to introduce regulations around digital intersections with workers on the ground.

Potential Unifor asks:

- Regulate industry to focus on worker augmentation instead of worker replacement when it comes to implementing safety, maintenance, and inspection technology.

- Review standards setting for any digital inspection technology.

- Expand regulation over the implementation of rail inspection and safety technology to include industry-wide minimum standards.

- Expand reach and funding of the Innovation Centre as a research institute under Transport Canada similar to the Volpe Centre.